Solution for Intelligent Beneficiation System

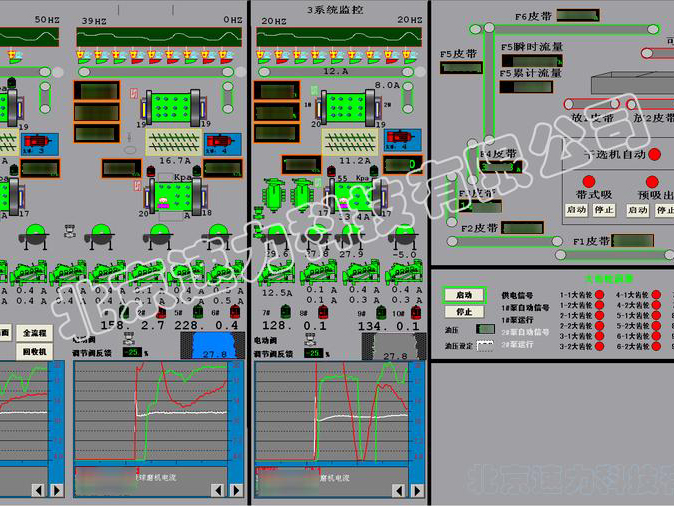

The technological process of beneficiation plant in metallurgical industry is mainly composed of production process of feeding, crushing and grinding, and the production environment is harsh with low level of automation. In some plants, manual feeding is even used, and the pulp granularity and concentration is observed artificially, and the feeder operation is adjusted according to the artificial judgment of the mill load. The adjustment is not timely and the operation is not stable, which often makes the mill "empty stomach" or "bulging belly", affecting the quality of the whole grinding and separation process. Therefore, it is of great significance to control the beneficiation plant intelligently.

At the same time, the characteristics of the technological process in beneficiation plants are that there are much large electric equipment, such as jaw crushers, grinders, and some high-voltage equipment, which generates large amounts of interference sources in production environment, such as high-voltage electromagnetic field interference, high-voltage signal interference, the interference of large-power equipment start/stop signal, etc.. Reasonable and effective anti-interference measures shall be used to ensure the control system can operate normally and stably.

The intelligent control system of beneficiation plant takes "simplicity, safety, practicality and reliability " as the principle, timely grasps and understands the changes of operation condition and process parameter of equipment in the technological process, optimizing technological process, ensuring stable and safe operation, reducing operating costs, improving management level. The whole process can normally and steadily operate in long term, to achieve optimum benefit.

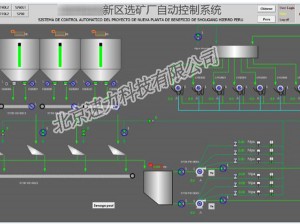

Combined with the general technological process in domestic beneficiation plant of metal mines, our company designs a set of intelligent control system suitable for the domestic metallurgical industry, and the characteristics of the system are shown as following:

Reliability and stability, which ensures the whole beneficiation process operates safely;

Applicability, which meets and optimizes the production and management of technological process;

Easy operation and maintenance, with simple and reasonable structure;

Compatibility, the system is the integration of hardware and software as a whole.

Extensibility, which reserves expansion pace for the system upgrade and technical transformation;

Openness, the control system has good openness.