Overall solution for Intelligent Underground mining

Background

With the transformation of old and new kinetic energy and the continuous advancement of supply-side structural reform, the society development has entered a new intelligent era. The traditional extensive development model is unsustainable, and the pressure of resource, economic and ecological security is increasing. In order to realize the transformation from a major mining power to a great mining power, and shape China's mining industry image in the new era, the mine construction in China must run down the innovative road.

Smart mines are based on improving mine productivity, and make full use of information technology to manage and control mine resources and enterprise production and operation, so as to build safe, efficient, less-worker, unmanned, green-development and high-quality mines.

Target

The Target of intelligent mines - use information technology to realize green, safe and efficient modern mines.

Green - the whole process of mineral resources development, scientific and orderly mining, and protecting ecological environment.

Safety – transfer dangerous, labor-intensive mines into less-worker and unmanned ones.

Efficient - Use information technology to effectively connect processes, equipment, personnel, and professions to ensure long-term stable operation.

System Composition and Architecture

According to the production process of underground mining, it mainly involves establishing resource reserve model- preparing planning- production and mineral proportioning - large fixed facilities - transportation statistics - planning monitoring and other production management links. The construction of intelligent mines adopts cutting-edge technologies such as the Internet of Things, big data, AI and 5G. Integrate intelligent technology and management to build a comprehensive new modern intelligent production management and control platform for underground mining.

Construction of intelligent management and control center

Data center

Adopting advanced design concepts combined with mature mainstream technologies, building the central computer room into an advanced data center, and building an open, shared, and collaborative intelligent manufacturing industry ecology is an important model and best practice for enterprise informatization construction. It is a necessary means for enterprise data information management and efficient utilization, and it is also a core capability for the sustainable development of enterprises.

Smart Decision Center

It uses the data in the data center to analyze and process it through query and analysis tools, data mining tools, intelligent modeling tools, etc., and finally presents the knowledge to managers to provide support for managers' decision-making process.

Intelligent operation center

As an intelligent operation center for enterprise strategy decomposition and implementation, its main functions are to realize collaborative operation among subordinate enterprises and with external stakeholders, as well as the unified balanced scheduling, collaborative sharing and optimal allocation of human, financial, material and other resources.

Intelligent production center

The intelligent production center is responsible for the automatic control and management of the whole mine production system and equipment. The system center equipment of the whole factory, such as wired and wireless communication, personnel positioning, closed-circuit monitoring and informatization are installed in the production center. Form a plant-wide control, display and monitoring center. An engineer station is set up to be responsible for the inspection and maintenance of the entire plant's equipment, network and other systems.

Intelligent maintenance center

The intelligent maintenance center conducts centralized and unified management and control of the company's maintenance and repair through the intelligent maintenance platform, integrates maintenance resources, deepens maintenance force, and escorts the stable operation of the company's production equipment.

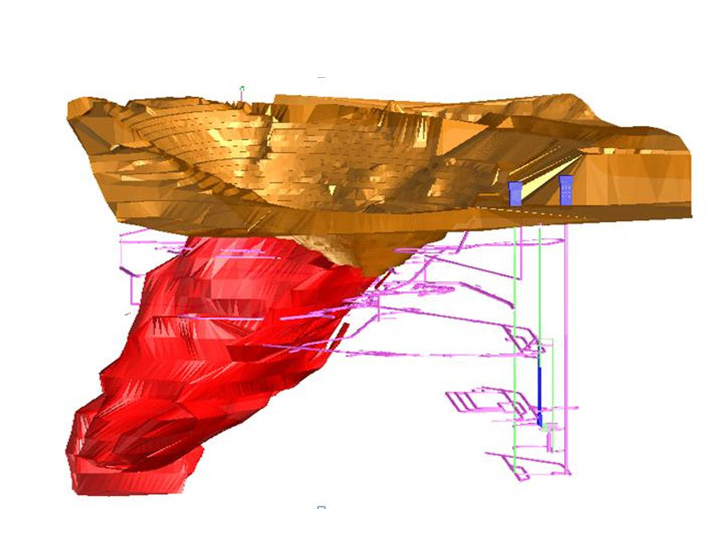

Digital mining system

Establish deposit geological database and rock classification database; establish surface model, ore body entity model, block model, rock mass classification model, etc.; through reasonable planning, optimize the layout of mining accuracy engineering , blasting design, etc. , to achieve safe, efficient and economical mining.

3D visualization control

The centralized visualization of underground mine safety production is realized through the 3D visualization platform. Based on the mine production, safety monitoring data and spatial database, the 3D visualization and virtual environment of mine resources and mining environment are used as the platform, using 3D GIS, VR and other technical means. Carry out 3D digital modeling for ore deposit geology, production process and phenomena, to realize real-time 3D display of mine production environment and safety monitoring, form 3D visual integration, and support production and operation management and control.

MES for underground mines

MES is an information system that optimizes and solidifies production process management with the goal of improving comprehensive production indicators. MES is not only a bridge between the level 2 and the level 4, but also a set of independent information system, which is a integrated platform that integrates the technological process, management process and decision analysis of mining enterprise, and integrates the advanced management concepts and excellent management experience of the mining industry.

The six systems for safety and escaping from danger

Personnel positioning,

Communication,

Water supply and rescue

Compressed air and self-rescue

Monitoring and detection

Emergency avoidance

Video surveillance system in the whole mining area

The video surveillance system proposes all-round solutions for video surveillance, signal transmission, central control, remote supervision, etc., which can realize the networking of the mine and the monitoring center, and make the mine safety management stride towards a scientific, standardized and digital management track, and improve the safety management level. The video surveillance system uses AI technology to automatically identify various violations such as personnel not wearing safety helmet and mining crossing the border.

Unattended system for large fixed installations

The equipment in central substation realizes remote power stop and start monitoring and monitoring, and finally realizes unattended operation.

The unattended system for underground water pump room realize the intelligent start and stop or remote manual start and stop.

The ventilation system is unattended. According to analyzing ventilation volume and collecting on-site data, to control the main fan and local fans to start and stop according to actual production principles. Realize automatic start and stop of the fan.

Remote control system of single trackless equipment

Intelligent mining aims at unmanned and autonomous operation of single equipment. On the basis of the underground communication platform having been constructed, seize the favorable opportunity of the rapid development of modern information technology represented by the current Internet of Things, big data, cloud computing, virtual reality, blockchain, 5G, etc., and take the single equipment as a breakthrough, research and implement remote control and automatic driving of key equipment, to provide a benchmark for constructing intelligent mines, and enhance the influence of the domestic mining industry .

Unmanned Track Haulage System

The system successfully combines communication, automation, network, mechanical, electrical, remote control and signal systems. The vehicle operation command is carried out with the optimal driving route and cost-benefit accounting method, which significantly improves the utilization rate, capacity and safety of the railway line. Accurate train positioning is achieved through odometers, positioning correctors, and speedometers. The train control system based on the wireless communication system and the signal centralized closed system realize the fully automatic operation of the underground rail transportation.

Construction of unattended main shaft, auxiliary shaft system

The control system of the hoist mainly includes two parts: the main control system and the monitoring system. The main control system is responsible for coordinating and managing the operation and alarm tasks, and realizes the travel control based on detecting the exact position and speed of the hoisting container through the shaft; the monitoring system is independent of the main control system of the hoist in hardware and software, mainly to complete judging sliding rope, over-rolling and over-speed, and realize the position and speed monitoring of the whole hoisting process.

Intelligent crushing, conveyor and lifting control system

Establish an automatic control system from the underground crusher to the main shaft lift, the entire system can be centrally monitored and managed by the ground control center, and the equipment can be automatically interlocked and protected to ensure safe, stable and efficient operation.

The intelligent control system for underground slope ramp traffic

Safety production has always been the top priority in the mining production. With the expansion of the underground mining range and the increase of transportation tasks, the number of underground transportation vehicles has gradually increased. If there is no reasonable management and control system for trackless vehicles, the vehicles cannot understand the traffic situations, which will easily cause the vehicles to be blocked in a certain area, resulting in frequent reversing of vehicles, a waste of fuel, low transportation efficiency, and accidents. Therefore, a flexible, adaptable, safe and efficient traffic control system is particularly critical.