High Quality Sintering Production Control System - Unattended Substation System – Soly Detail:

Target

Three traffic signal machines are set at the entrance and exit of the ramp and the entrance and exit of the passing track. The signal system adopts automatic and manual two-way control. Via ground induction coils and WIFI equipment positioning technology, vehicles are measured which can be tracked and displayed throughout the whole process. The communication between dispatching room and vehicles, the communication among vehicles directly is connected by WIFI. The system realizes the unmanned on-site command and fully automatic operation mode.

System composition

(1) Entrances, passing tracks, and three -way intersections, including main road– > auxiliary road, auxiliary road– > main road, drift- > auxiliary road, all need to install no straight-travel and straight-traveling signs. And install no left and no right signs at the fork road.

Install ground induction coils at key points which are used to detect the running conditions of vehicles. Since there is a full coverage of the WIFI signal in the ramp, positioning tags can be used to assist positioning vehicles. Based on the above detection, the system logically judges and directs the vehicle to run.

(3) The signal lights are controlled by Siemens PLC. Considering that the up-vehicle has the priority to pass the road section. When it is detected that there is an upward vehicle passing by, the signal light on the opposite road section will sign stop to make the downward vehicle enters the passing tack for waiting.

(4) The system also has the following functions:

1. Real-time display the ramp map, ground induction coils, the distribution of signal machines in the ramp, and the status of signal lights.

2. Display the direction of vehicles in each section, whether there are vehicles in the section and the number of vehicles.

3. Display the alarm screen: the system will automatically alarm if there is vehicle violation or the vehicle stays in the ramp too long. Alarm content includes: time, location, type.

4. Manual control functions of signal lights. When abnormal operation occurs in the ramp, manual control can be performed to switch the signal.

Effects

Reliable vehicle identification technology improves the system safety factor;

Flexible traffic rules meet the needs of underground transportation;

Intelligent traffic control mode to promote innovation in production management;

General industrial control system is expandable, simple and practical.

Effects

Unattended weighing system: The system supports multi-media such as IC card, vehicle number identification, RFID, etc., and various application scenarios such as weighing with drivers getting off or not getting off the vehicle, and early warning of various special situations such as overweight and overload management and control, sold quantities being over-provisioned management and control, and the original purchased raw materials.

Financial settlement: directly connect with the financial system, and the data is synchronized with the financial system in real time. Contract settlement and pricing management can also be performed based on measurement and laboratory data.

Mobile APP: Through the application of cloud platform + metering APP, managers can conduct customer management, dispatching management, real-time data query, and abnormal reminders through mobile terminals.

Big data processing platform: logistics information such as logistics dynamics, weighbridge operation, etc. is clear at a glance.

Effect and Benefit

Effects

Solidify the logistics management process and standardize the logistics management business.

The transition from human defense to technical defense reduces management risks and plugs management loopholes.

The quality data cannot be changed which is seamlessly connected with the financial system.

The intelligent logistics development has driven the improvement of the overall intelligence level.

Benefits

Reduce personnel participation and reduce labor costs.

Eliminate fraudulent behaviors such as lost goods and one vehicle of materials weighing repeated, and reduce losses.

Improve operation and maintenance efficiency and reduce operation and maintenance costs.

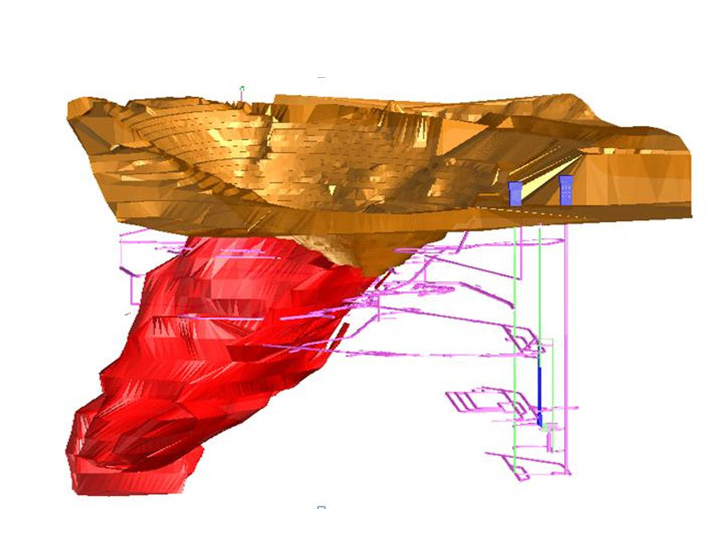

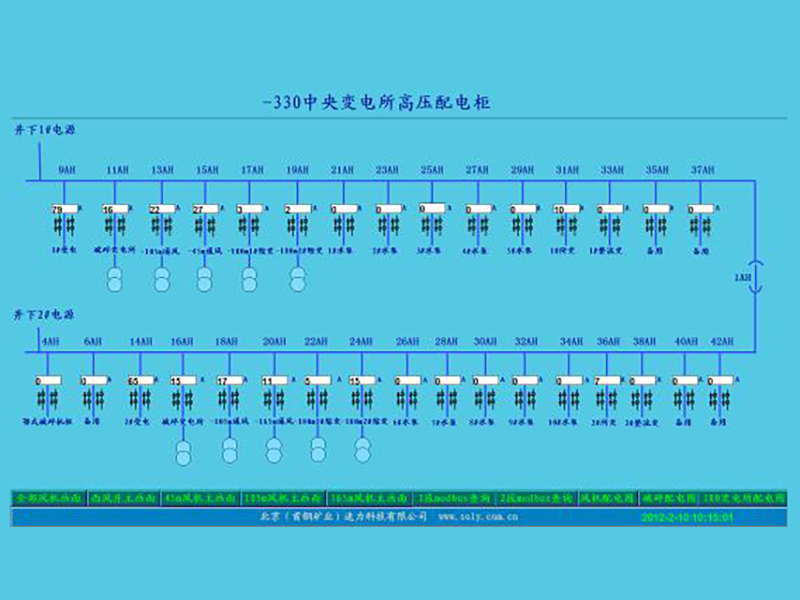

Product detail pictures:

Related Product Guide:

We take pleasure in an exceptionally excellent status between our buyers for our superb merchandise good quality, aggressive price tag and the greatest support for High Quality Sintering Production Control System - Unattended Substation System – Soly , The product will supply to all over the world, such as: Paraguay, Nigeria, Amman, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.