High Quality Intelligent Overall System For Open-Pit Mines - MES System – Soly Detail:

Background

With the rapid development of science and technology, the industry in the world has entered a new development epoch. Germany proposed “Industry 4.0″, the United States proposed the “National Strategic Plan for Advanced Manufacturing”, Japan proposed the “Science and Technology Industry Alliance”, and the United Kingdom proposed “Industry 2050 Strategy”, China also proposed “Made in China 2025″. The fourth industrial revolution also provides an opportunity to the promoting MES, and the extensive application of ERP and PCS in manufacturing enterprises also provides a good foundation for MES. But for now, the understanding and implementation of MES varies from industry to industry, and the development is unbalanced in different regions. Therefore, industries and enterprises should choose MES suitable for their own development according to their own conditions and characteristics to solve the problems that the traditional manufacturing information systems and process control systems are lack of information connection. Therefore, implementing MES in manufacturing nterprises is of great significance.

First of all, MES is not only an important part of the implementation of Industry 4.0, but also an effective means of deep integration of the two industries which has attracted more and more attention. MES has become the core management system for enterprise transformation, upgrading and sustainable development.

Second, the current market situation in the mining industry requires in-depth implementing enterprise fine management, which requires implementing MES that can realize production management informatization in factory, mine, workshop, and manufacturing execution process monitoring informatization.

Third, monitoring the mine production process is inconvenient, and the standard of process control stability is difficult to meet. MES realizes the transparency and scientific management of the production process in factories, mines and workshops. It can timely find out the root that causes problems affecting product quality and consumption costs, improve the real-time and flexibility of planning, and at the same time improve the output efficiency of the production line

which makes the process line produce the designed output or beyond the design capability.

Target

The solution for MES provides enterprises with an effective way that can realize transparent management in the production process. It is an information management system with production management as the core, helping enterprises to establish an integrated and transparent production site process control management platform, and to build a complete production process database which can real-time monitoring and comprehensive traceability in the production process, and continuously improve product output and quality through statistical analysis of data, so as to continuously improve market influence.

System Composition and Architecture

Taking production process as the principal line, based on real-time industrial data such as automation, measurement, and energy; MES runs through professional management process such as production, quality, scheduling, equipment, technology, procurement, sales, and energy, covers twelve functional modules, that is management, technical management, production shipping, production scheduling, production control, product inventory, material management, equipment management, energy management, quality management, measurement management, system management.

Benefit and Effect

The main management effects are as follows:

The management level has been significant improved.

Strengthen centralized management, form a collaborative mechanism, and promote collaborative management

Weaken functional management and strengthen process management.

Promote standardized management and improve execution.

Promote refined management and strengthen management intensity.

Improve management transparency and increase management binding.

The management efficiency has been significant improved

The system can reflect production, measurement, quality, logistics and other data timely and dynamically, and can be queried and applied at any time.

Data and information are got from the lowest level of measurement, quality inspection, equipment acquisition or automatically generated by the system, which is timely and accurate.

Leaders and managers at all levels are freed from a large number of repetitive tasks with low management content.

In the past, work that required manual methods and took a lot of manpower and time is now transformed into simple and short-lived work with the help of information technology, and the work efficiency has been improved hundreds of times.

Management foundation has been strengthened

Provide true and accurate data. From manual input to direct collecting from automated instruments and meters into the secondary database for processing and sorting, the data is transparent whose authenticity can be guaranteed.

Accelerate data analysis and response. The system automatically forms a visual report board, which can make you pays attention to the real-time production situation on site in real time at any places.

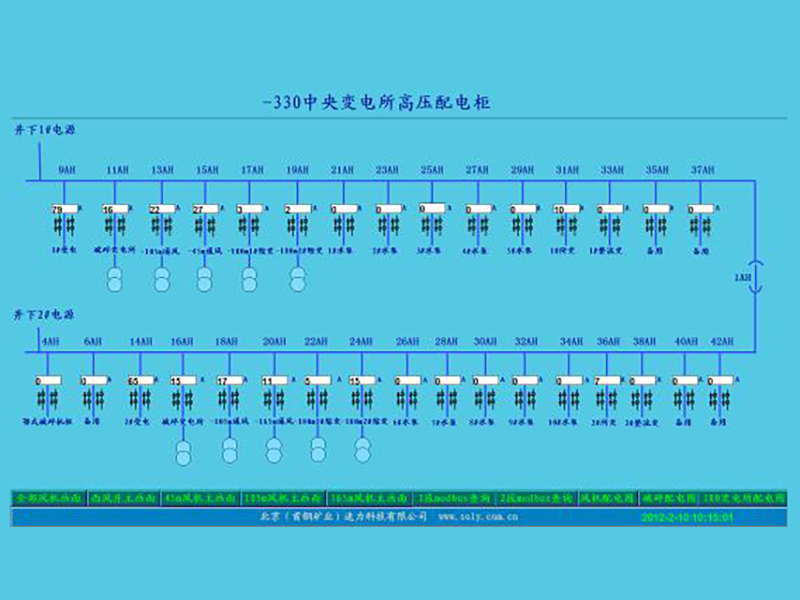

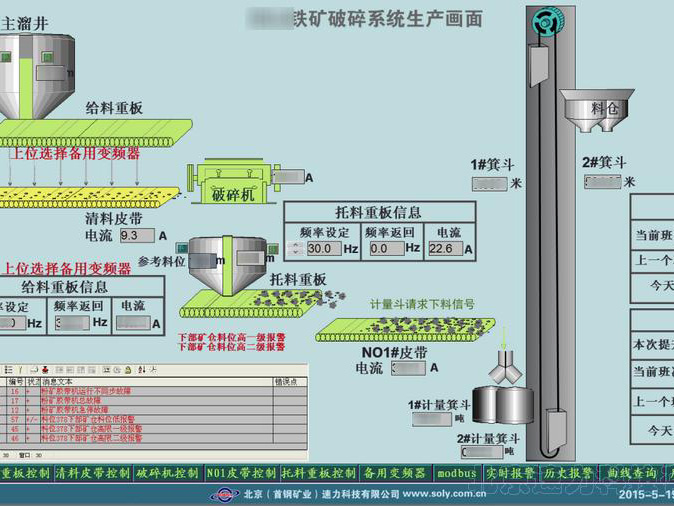

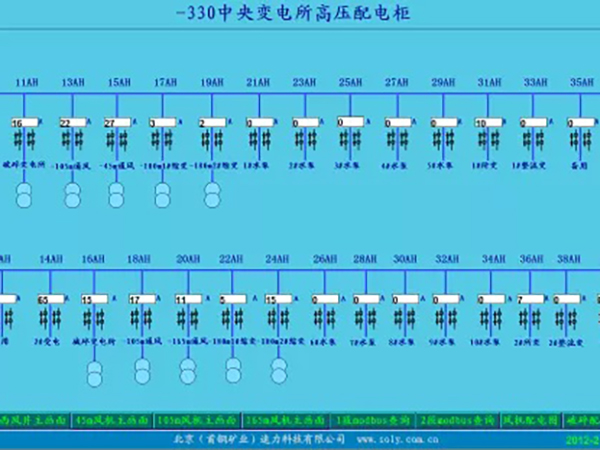

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for High Quality Intelligent Overall System For Open-Pit Mines - MES System – Soly , The product will supply to all over the world, such as: Victoria, Doha, Cambodia, With a wide range, good quality, reasonable prices and stylish designs, our items are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.